Brewing a Brighter Future: Drake’s Brewing Transitions to Recycled Packaging | Grocery

10/15/2024

RRD’s packaging solutions enable Drake’s Brewing Co. to deploy 100%-recyclable and compostable FSC®-certified product packaging

CHALLENGE

The founders of Drake’s Brewing Company began brewing beer inside a former car factory in 1989. Today, the award-winning brewery is one of the largest independent brewing companies in the San Francisco Bay Area, and ranks as one of the top 50 craft brewers in the United States. Committed to a culture of innovation, the company recently sought to minimize their carbon footprint and maximize opportunities for increased sustainability — a core company value.

For distribution at leading national retail outlets, the brewery had already transitioned from bottles to cans. Because cans are lighter and take up less space, this switch enabled Drake’s to ship more beer per truckload. This led to considerable fuel savings and a reduction in emissions.

Already an industry leader in sustainability, the brewery learned during a consultation with RRD that although their existing packaging material was recyclable, it was being produced with virgin fiber as opposed to recycled board. Upon this discovery, the brewery sought external support to transition to recycled, responsibly sourced 6-, 12-, and 15-pack carrier packaging.

SOLUTION

Drake’s turned to RRD’s packaging experts to provide a solution that could meet their packaging and sustainability needs. To ensure the brewery’s expectations would be met, RRD set up regular consultations, hosted status meetings, and worked alongside internal client teams throughout the project’s timeline.

“We are always looking for opportunities to decrease our overall carbon footprint. We look at how environmentally friendly a solution is, how it can help decrease our environmental footprint, any alternatives that might be better from a financial perspective, and so on,” says Drake’s Sustainability Manager Hal McConnellogue. “It was a no-brainer that this was the direction we wanted to go in — increasing the sustainability of our product packaging.”

To ensure their packaging was sourced from responsibly managed forests, RRD identified a 100%-recycled compostable Forest Stewardship Council® (FSC)-certified beverage board that met all of Drake’s sustainability and financial requirements. Specifically produced for beverages and specialty made for refrigerated conditions, the material was chosen to ensure the packaging would be both sustainable and durable.

To ensure their packaging was sourced from responsibly managed forests, RRD identified a 100%-recycled compostable Forest Stewardship Council® (FSC)-certified beverage board that met all of Drake’s sustainability and financial requirements. Specifically produced for beverages and specialty made for refrigerated conditions, the material was chosen to ensure the packaging would be both sustainable and durable.

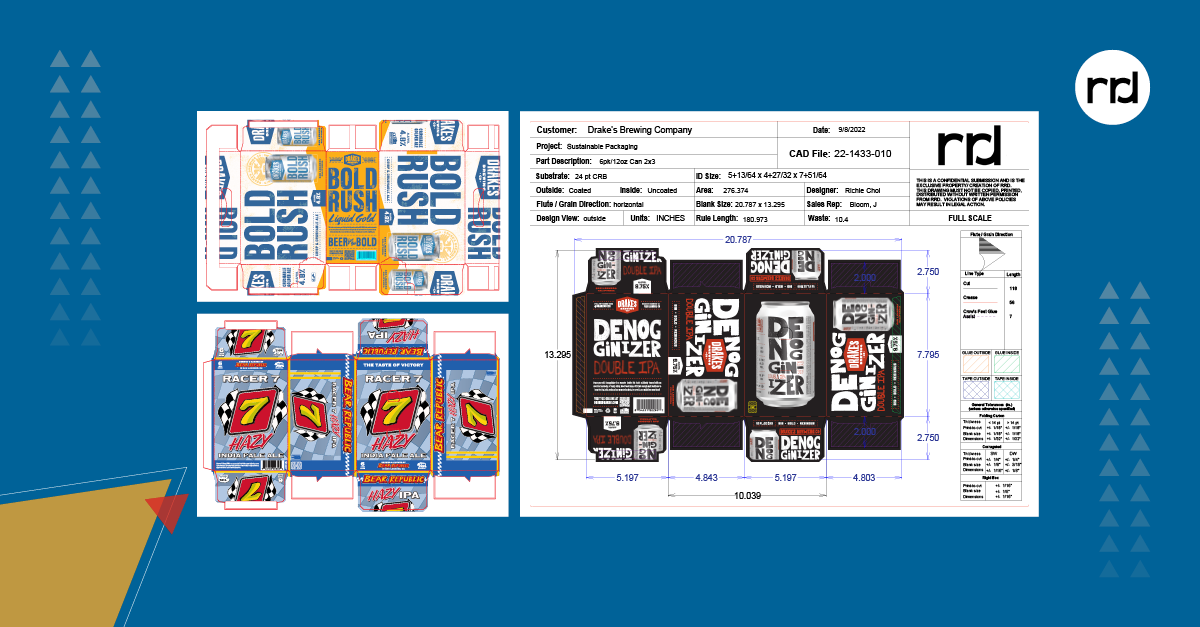

RRD created new packaging prototypes by cutting samples of the existing packaging structure onto new board material. These prototypes were brought to Anthony Raggio, Drake’s Director of Packaging & Logistics, for materials testing. After a successful evaluation, the structure and artwork were proofed and approved.

“We are proud of the sustainability improvements we’ve made, and look forward to utilizing FSC paperboard for the foreseeable future,” says Raggio.

The new FSC-certified packaging — featuring the official FSC logo — is now in stores. As a result, the brewery is able to clearly demonstrate their strong commitment to increased sustainability.

RESULTS

“Drake's is continuously committed to being a force for positive change in a rapidly evolving world,” stated McConnellogue. “As we strive to minimize our environmental impact, we are actively seeking opportunities to reduce carbon emissions and waste. Our goal is to contribute meaningfully to a more sustainable planet, and by continuously improving our practices, we aim to ensure that future generations inherit a world that is as vibrant and resilient as our own.”

Drake’s partnership with RRD has yielded an impressive array of benefits, including:

- Introduction of FSC-certified, 100% recycled paperboard, providing increased sustainability and adherence to Drake’s long-term business objectives

- RRD carton packaging for the company’s 12-oz. and 19.2-oz. formats, enabling the brewery to reduce Scope 3 emissions related to distribution by 4%

- Utilizing RRD cartons generates 25% less paperboard waste in the manufacturing process than the company’s previous packaging format

- The packaging format change — from bottles to cans — has enabled Drake’s to ship 46% more volume per full truckload (FTL)

- Switching to RRD wraps for can packaging has diverted 32,792 lbs of waste from the landfill over the past year

CONTACT US